PACKING & LABELLING

20 LIT JAR AUTOMATIC RINSING FILLING & CAPPING LINES

Aguapuro provides Complete automatic 20 Lit / 5 Gallon RInsing Filling Capping Lines. Capping for Press Fit Type & Screw Type are available and can be customized as per requirement. Capacities ranging from 200 Jar per hour to 600 Jar per hour are available.

Also Lines for Filling 5 / 10 Litre PET jars are available from capacities ranging from 200 to 400 bottles per hour @ 5000 ml

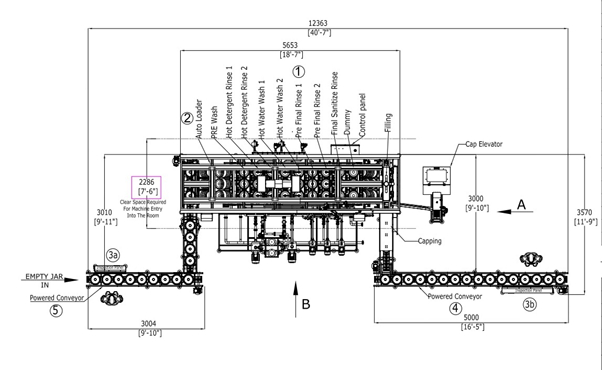

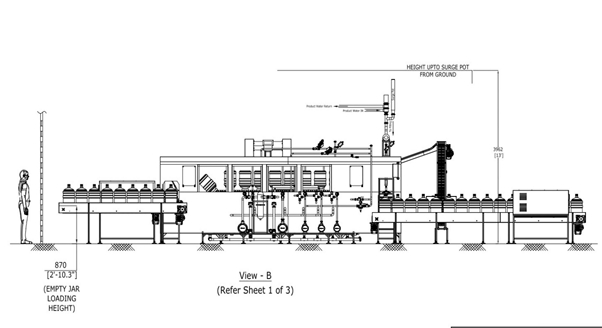

General Schematic of a high speed line

WORKING PRINCIPLE OF THE MACHINE:

The operation of the machine is in linear direction.

Loading of Jars:

The operator has to place the jars in invert position on the conveyor for the full line process. A guide track is provided which supports the movement of the jars.

Rinsing Stage:

The jar moves forward for the rinsing application to take place and comes over the first internal /external rinsing nozzle, here the jar is been rinsed by plain water (Depending what you provide for rinsing). This plain water rinsed jar then moves towards the second internal/external-rinsing nozzle, here the jar is been rinsed by soap water. (Depending what you provide for rinsing).

This soap water rinsed jar then moves towards the third internal/external-rinsing nozzle, here the jar is been rinsed by hot water. The above jar then moves forwards to the final internal rinsing nozzle, here the jar is been rinsed by product water.

Filling Stage:

Further this fully rinsed upside down jar automatically falls on the next moving filler conveyor with the required orientation for filling process. The jar moves forward towards the filling unit where with the help of Double nozzle filling operation takes place.

Capping Stage:

After filling the jar moves forward on the running conveyor for capping operation to takes place. When this fully filled jar moves forward, caps are automatically placed over the mouth of the jar by a chute arrangement from the cap dispenser. Here a U.V. light is placed for the sterilization of caps. Vibrator is provided above the conveyor in which the operator has to load the caps manually in the hopper. The cap placed jars moves forward on the conveyor and the caps are automatically pressed on the jars by Cap pressing cylinder unit.

Inspection stage:

The jar is further pushed on the same conveyor towards the inspection light.

Unloading stage:

After inspecting the filled jars, further the jar is manually unloaded from the running conveyor by the operator.

Seperate JAR OUTER & INNER BRUSHING UNITS CAN ALSO BE PROVIDED