LIME DOSING

Lime is used by many municipalities to improve water quality, especially for water softening and arsenic removal.

Softening

In water softening, hydrated lime is used to remove carbonate "hardness" from the water. Hardness caused by other calcium and magnesium salts, called noncarbonate hardness, is generally treated by means of the lime-soda process, which entails the precipitation of magnesium by lime.

pH adjustment

Lime is widely used to adjust the pH of water to prepare it for further treatment. Lime is also used to combat "red water" by neutralizing the acid water, thereby reducing corrosion of pipes and mains from acid waters. The corrosive waters contain excessive amounts of carbon dioxide. Lime precipitates the CO2 to form calcium carbonate, which provides a protective coating on the inside of water mains.

Effect on pathogen growth

By raising the pH of water to 10.5-11 through the addition of lime and retaining the water in contact with lime for 24-72 hours, lime controls the environment required for the growth of bacteria and certain viruses.

Lime Dosing System is installed with following components:

- Single or compartment solution preparation tank.

- Chemical dosing pumps single or multiple

- Valve’s fittings

- Interconnecting piping

- Instruments like pressure gauges

- Level gauges, level switches

- PRV

- Sensors

- Control panel including interconnecting cabling

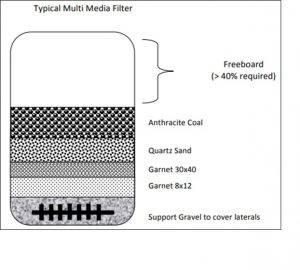

Multimedia filtration refers to a pressure filter vessel which utilizes three or more different media as opposed to a “Sand filter” that typically uses one grade of sand alone as the filtration media. In a single media filter, during the “settling” cycle, the finest or smallest media particles remain on top of the media bed while the larger, and heavier particles, stratify proportional to their mass lower in the filter. This results in very limited use of the media depth since virtually all filterable particles are trapped at the very top of the filter bed or within 1-2 inches of the top where the filter media particles have the least space between them. The filter run times are thus very short before the filter “blinds” or develops so much head pressure that it must be backwashed to avoid seriously impeding or stopping the flow.

Multi-media water filters typically utilize three layers of media for multimedia filtration: anthracite, sand and garnet. These media are often chosen for use in multimedia filters due to the distinct differences in their densities. Anthracite is the lightest filtration media per unit volume, followed by sand, and then garnet.

The idea behind using media with differing masses is that during backwashing the lightest media with the largest particles (anthracite) will naturally stratify at the top of the filter, while the intermediate sized media (sand) will settle in the middle, and the heaviest media with the smallest particles (garnet) will settle to the bottom.

This layering of the filtration bed encourages the very largest contaminants to become trapped in the first layer of the filter, with smaller particulates sifting farther down into the lower layers. Trapping contaminants in this manner allows for more efficient turbidity removal and for longer run times between backwash cycles. A simple sand filter can be expected to eliminate particles down to 25-50 microns in size, as compared to a multimedia filter that can remove particles down to 10-25 microns.

Operating at higher pressure differential is liable to drive particles so deeply into the media bed that backwash is not able to remove them all. Over time the build-up of dirt deep in the filter will cause shortened filter runs and high differential pressures. Filter backwash may include air scour to help loosen packed dirt in the media bed. When this step is included, it is preceded in the backwash cycle by a “drain down” period for water to be bled out of the filter vessel.

Flocculants / coagulants may be used upstream of the filter to induce the tiny dirt particles to join together to form particles large enough to be removed by the filter. This process is called “agglomeration” and, with proper chemical dosage, adequate mixing and adequate contact time, it will enable the filter to remove particles below 10 microns in average diameter.

| Media | Effective size, mm (in.) | Specific gravity |

| Anthracite | 0.7-1.7 (0.03-0.07) | 1.4 |

| Sand | 0.3-0.7 (0.01-0.03) | 2.6 |

| Garnet | 0.4-0.6 (0.016-0.024) | 3.8 |

| Magnetite | 0.3-0.5 (0.01-0.02) | 4.9 |

Here, our expertise in designing these systems allow efficient handling of storage, metering, mixing, dilution and dosing of soluble solid and liquid reagents. Further, the high automation and control delivered ensure all aspects of process control inputs are well accommodated in the systems.

When is a Multimedia Filter required?

A multimedia filter is suggested when the Silt Density Index (SDI) value is greater than 3 or when the turbidity is greater than 0.5 NTU. There is no exact rule, but the above guidelines should be followed when better filtrate water quality is required or to prevent premature Fouling of RO membranes.

The Benefits of Multimedia Filtration over Conventional Sand Filters

Unlike traditional sand filters, Multi-Media filters are composed of three filtration media, ordered in decreasing porosity. Because of their multi-layer design, multi-media water filters are able to trap and retain a far larger number of particles than traditional sand filters before backwashing becomes necessary.

Trapping sediment and particulates throughout the entire depth of the filter bed, allows multi-media water filters to operate for much longer periods of time than conventional sand filters. The process of multimedia filtration produces high quality, filtered water at much faster flow rates than traditional sand filtration.

Aguapuro offers wide series of multimedia filters for removal of suspended solids and heavy metals.

These Filters are available in

- Mild Steel Epoxy Painted (MSEP) or Rubber Lined (MSRL) and

- Stainless Steel 304 or 316 Grade

- FRP (Fibre Reinforced Polymer),

Filters are available in standard sizes ranging from 300 mm dia up to 4500 mm dia with straight height of 2000 mm for Flow Rate starting from 1000 Lts per hour up to any size.

Read more