POSITIVE DISPLACEMENT PUMPS

Positive displacement pumps are classified into different types but some of them are discussed below like diaphragm, gear, peristaltic, lobe, and piston pumps.

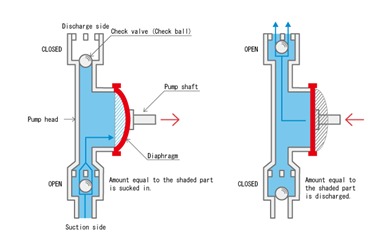

1) Diaphragm Pumps

Diaphragm pumps also known as AOD pumps (Air operated diaphragms), The applications of these pumps mainly include in continuous applications like in chemical / potion dosing systems

These pumps are also utilized for transferring chemical potions in relatively precise flow

Applications :

- Mineral dosing systems in Bottled water

- Nutrient dosing in Food & Beverage Industries

- Chemical dosing in water treatment

- Chemical dosing in Waste water applications

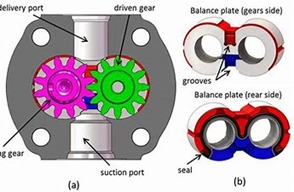

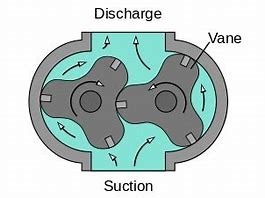

2) Gear Pumps

These pumps are a kind of rotating positive dislocation pump, which means they force a stable amount of liquid for every revolution. These pumps move liquid with machinery coming inside and outside of mesh for making a non-exciting pumping act. These pumps are capable of pumping on high forces & surpass at pumping high thickness fluids efficiently.

A gear pump doesn’t contain any valves to cause losses like friction & also high impeller velocities. So this pump is compatible for handling thick liquids like fuel as well as grease oils. These pumps are not suitable for driving solids as well as harsh liquids. But are used in High viscous application like Fruit / Veg Pulp transfer in beverage industries

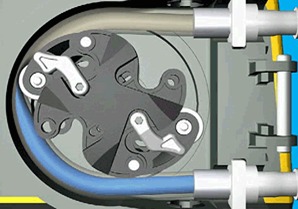

3) Peristaltic Pumps

Peristaltic pumps are also named as tube pumps, peristaltic pumps. These are a kind of positive displacement pumps and the applications of these pumps mainly involve in processing of chemical, food, and water treatment industries. It makes a stable flow for measuring & blending and also capable of pumping a variety of liquids like toothpaste and all kinds of chemicals.

4) Lobe Pumps

These pumps offer different characteristics like an excellent high efficiency, rust resistance, hygienic qualities, reliability, etc. These pumps can handle high thickness fluids & solids without hurting them. The working of these pumps can be related to gear pumps, apart from the lobes which do not approach into contact by each other. Additionally, these pumps have superior pumping rooms compare with gear pumps that allow them to move slurries. These are made with stainless steel as well as extremely polished.

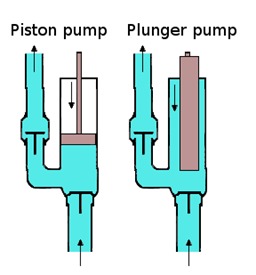

5) Piston Pumps

Piston pumps are one kind type of positive dislocation pumps wherever the high force seal responds through the piston. These pumps are frequently used in water irrigation, scenarios requiring high, reliable pressure and delivery systems for transferring chocolate, pastry, paint, etc.